Between technology and design

Expomobilia AG has optimized its sheet metal storage by investing in a STOPA ECO tower storage system. The reason for this was the desire for more ergonomics. The company has achieved this goal. In addition, the handling of the sheets is now much more efficient. And that applies from delivery to processing.

Markus Halbeisen, Head of Operations and Member of the Board of Expomobilia AG in Effretikon near Zurich, shows photos of a pallet rack in which three types of sheet metal with different thicknesses and dimensions used to be stored on each level. “If we needed a sheet that was at the bottom, it took a lot of sorting and rearranging. “ A problem that has become even more acute due to the growing stock. Especially since the exhibition stand builder often needs new types of sheet metal due to the design-oriented character of his stand elements. Because the stocks are also increasing due to the remaining sheet metal of customer-specific types, Expomobilia had decided to optimize the storage and material flow.

On his tour, Halbeisen stops in front of the tower storage system, which was supplied by STOPA Anlagenbau GmbH, Achern-Gamshurst. “Since we have been using the storage system, the 28 most common of our approximately 40 types of sheet metal are stored there. This means that we can access individual sheets more quickly and without having to move them. We also benefit from faster storage. “ Ultimately, the entire handling process, from delivery to processing, is more efficient and faster. Other investments, such as a slewing crane with a suction gripper that can be used to lift the sheets from the pallets, also contribute to this. This means that employees hardly have to lift any loads at all. The days when damage occurred when handling thin sheets are also over. Christian Graf, team leader of the metalworking shop, asks his employee Ernst Spirig to move a pallet out of the tower to demonstrate the convenient handling of the load carriers. “STOPA has fulfilled our ergonomic requirements with the tower storage system. In addition, we now support the complete material flow with the aid of tools.”

Good use of space in a small area

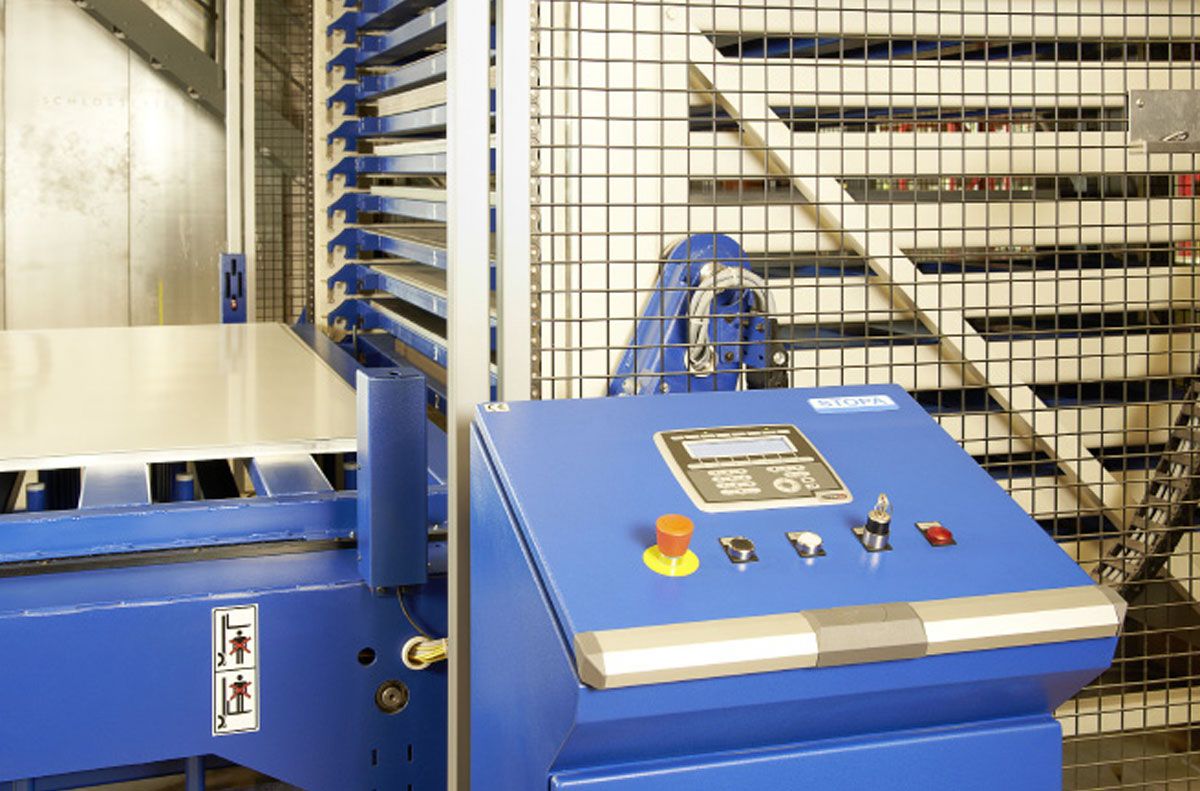

Expomobilia triggers material retrieval from the system control panel by entering the number of the pallet to be retrieved.

The STOPA ECO, in which Expomobilia stores pallets lengthwise, offers an affordable entry into the automatic storage of flat goods materials thanks to its modular concept. It is suitable for workshops and companies that buffer a wide range of materials in relatively small quantities. In this case, the tower is 4.9 meters high, 3.35 meters long and 4.1 meters wide, and it has 28 storage spaces. The system’s flat pallets consist of a self-supporting frame construction with longitudinal profiles and sliding rails and are designed for large-format panels (1,525 x 3,050 millimeters) and payloads of up to 1,200 kilograms.

Thanks to its compact design, the tower achieves a high degree of space utilization with little space requirement. To further improve the packing density, STOPA has provided the rack block with a fixed height grid. If the operator works with the double height grid, he can also store higher goods, such as Euro pallets. The rack block, which forms a secure steel construction system with longitudinal connections and diagonal reinforcements in its frame, is equipped with pallet supports that are secured against sliding through at the back.

Company

Expomobilia AG: Making the impossible possible

Expomobilia AG, Effretikon near Zurich, was founded in Switzerland in 1973 and is active worldwide. The company specializes in exhibition stand construction and creative brand staging in three-dimensional space. The company, which employs 110 people, 25 of whom are project managers, develops concepts to production readiness in its technical competence center. It offers a full range of services in exhibition stand construction, from design and conception to the assembly of a stand.

Expomobilia stands for punctuality, high flexibility and quality, as well as for quick-wittedness. The motto is always: making the impossible possible. In 2013, the subsidiary of MCH Group AG celebrated its fortieth anniversary. Business partners benefit from 40 years of international experience and a broad range of expertise in terms of customer-oriented solutions for stand construction. And this in a range from small to luxurious.

If the company’s own production depth is too small or if parts for the stand design are too large to be transported over long distances, Expomobilia draws on support from external networks in Switzerland and from international networks. In Switzerland, the company is able to respond overnight and quickly fulfill customer requests through its own services.

Expomobilia AG specializes in exhibition stand construction and creative brand staging in three-dimensional space.

The processes

By investing in the STOPA ECO, Expomobilia can access individual panels faster and without having to move them.

Forklift trucks unload the sheet metal packages from the delivery trucks and place them on the fixed storage stamps of the storage platform. Between the stamps, the robust two-mast load traverse of the single-sided tower storage system, which works with a pull-and-push device for storage and retrieval, has already lowered a flat pallet. The stationary crossbeam, which is equipped with a low-wear and low-maintenance chain hoist and is positioned in height by an absolute and load-independent digital distance measuring system, lifts the loaded pallet and stores it with the sheets in its firmly assigned place in the rack block. Graf points to the 28 flat pallets stacked tightly on top of each other. “We hardly ever have to add to our stock because we only reorder sheet metal once our reserves have been used up as far as possible. However, we do store leftover sheets if they still have more than half of their original dimensions.” The storage platform can be moved by hand on rollers to access the lowest levels. Spirig triggers the retrieval of material from the system control panel by entering the number of the pallet to be retrieved. He then lifts the individual sheets from the load carriers using the slewing crane.

The types of sheet metal stored in the STOPA ECO differ in terms of their dimensions, thicknesses and materials. Expomobilia uses stainless steel, steel and aluminum. Since the operator only supplies its own metalworking shop from the sheet metal store, the tower only contains the sheets that it needs there for a press brake and a sheet metal shear. The handling capacity is around 30 tons per year. In view of this quantity, the Swiss company is now able to purchase the sheets in packages and thus more economically due to the larger storage capacity. Sheets that the company has laser, water jet or plasma cut externally are stored at other locations.

Desire for more ergonomics implemented

With the tower storage system, STOPA has fulfilled Expomobilia’s demand for ergonomics.

The sheet metal warehouse was opened in January 2012. Halbeisen shows another photo. “I gave a speech at the opening ceremony. Then we drove out the top pallet, on which, to the surprise of the employees, as you can see in the picture, there were sandwiches.” But that was by no means the only reason for their boost in motivation, as Halbeisen emphasizes. The employees are also happy about the sheet metal storage system because they no longer have to lift the sheets out of the shelf in pairs. Today, one person can do this more ergonomically and with less effort. In this respect, the ease of use of the tower was essential in fulfilling Expomobilia’s desire for more ergonomics.

Broad range of requirements

Markus Halbeisen, Head of Operations, Member of the Board of Expomobilia AG in Effretikon near Zurich.

Halbeisen pulls a folder out of a shelf and opens it. “We asked three suppliers at the same time. The decisive factors in favor of the STOPA ECO were, in addition to the ergonomic and easy handling, the good price-performance ratio, the easy operation of the storage system and its visual design. In addition, the storage system meets our technical requirements and its capacity matches the throughput volumes of our production. Other advantages of STOPA, compared to the competition, were the loading height of up to 60 millimeters and the system height and length. We also cited the optimization of the material flow and the high level of occupational safety as reasons for the investment to the MCH Group, our parent company.«

Author: Jürgen Warmbol

Sales Contact Person

Holger Dehmelt

Sales Engineer Warehouse Technology

STOPA Anlagenbau GmbH

Industriestr. 12

77855 Achern-Gamshurst

Rolf Eckhardt

Sales Engineer Warehouse Technology

STOPA Anlagenbau GmbH

Industriestr. 12

77855 Achern-Gamshurst

Andreas Pahl

Sales Engineer Warehouse Technology

STOPA Anlagenbau GmbH

Industriestr. 12

77855 Achern-Gamshurst