Automatic sheet-metal storage system extends capacity

By extending its STOPA UNIVERSAL automatic storage system, which is designed for sheet metal in sizes up to the maxi format XF, SEEGER Lasertechnik GmbH has expanded its capacity. In addition, the automatic connection of a laser cutting system has taken a significant step towards greater productivity.

Roland Kiefer, managing partner of SEEGER Lasertechnik, Lorsch, starts the tour on a high machine platform that provides a comprehensive view of his sheet metal storage and plant supply. “We feed our old systems manually with sheets using a crane. We had the new machine automatically connected to the storage system.”

The opportunity to connect an additional laser cutting machine and, in the future, even more machines to the storage system from STOPA Anlagenbau GmbH, Achern-Gamshurst, arose due to the expansion of capacity and the extension of the system. Originally, the sheet metal storage system was 7.5 meters high, seven meters wide and about 31 meters long. Today, the system extends over a length of around 55 meters. A distance over which the double-mast storage and retrieval system (SRM) reaches a speed of up to 100 meters per minute. SEEGER has also used the expansion of the warehouse to integrate further stations.

Oriented towards the future

By extending its automatic sheet metal storage system, SEEGER Lasertechnik has expanded its capacity limits

Kiefer is holding a sketch and a folded laser part in his hands. “As a system supplier, we offer everything from a single source, from design to finished product. From simple ready-to-install laser parts to large series and complex assemblies, including coloring. In this respect, the expansion of our automated warehouse is a signal. Especially since it allows us to align our performance with growing demands.«

SEEGER manufactures laser parts and assemblies made of steel, stainless steel, aluminum and non-ferrous metals. Depending on customer requirements, components are also bent and welded. In addition to the sheets, the company also cuts tubes. In total, the daily production volume is around a thousand different parts.

According to Kiefer, the flexibility of the storage system, in which raw materials up to the 2,000 x 4,000 millimeter large Maxiformat XF as well as semi-finished parts, for example blanks, are stored, contributes equally to productivity. In addition, the STOPA UNIVERSAL, which stands for fast access to the sheets and a high degree of space utilization, can be networked with TRUMPF systems without interface problems. This is an aspect that, in his experience, does not work with storage systems from other suppliers, which SEEGER also considered before the original commissioning in 2008.

Kiefer points to the processing machines. “Contrary to the usual positioning, we had our systems turned 90 degrees to face the warehouse. This allows us to benefit from an increase in space and to connect twice as many systems. To save space in depth, we decided to use machines with a platform design and mounted the control cabinets on them.”

Highlights of the solution

- By extending the warehouse, SEEGER Lasertechnik has expanded its capacity limits.

- The flexibility of the storage system, in which raw materials up to the 2,000 x 4,000 millimeter large Maxiformat XF as well as semi-finished parts are stored, contributes to the operator’s productivity.

- Since the processing machines are aligned at 90 degrees to the warehouse, in contrast to the usual positioning, twice the number of systems could be connected.

- Because the automatic handling system of the laser cutting machine communicates directly with the automated storage system, the production processes can be controlled even more efficiently. This is an advantage that points towards Industry 4.0 in the metal industry.

Industry 4.0 in the metal industry

In addition to expanding the sheet metal storage system, STOPA has integrated three additional stations. The operator uses two of these as incoming and outgoing goods stations. One of the stations is equipped with a double carriage to which a TRUMPF TruLaser 5030 fiber flatbed laser machine is connected using the LiftMaster automatic handling device.

The system loads the machine via a lower carriage equipped with a last-sheet detection system. A gantry-type upper carriage transports semi-finished parts and scrap sheets back to the warehouse.

The gantry is equipped with a contour control system that checks the correct position of the sheets on the pallet when they are returned to storage. Kiefer is watching an unloading process. “Since the LiftMaster of the laser cutting system communicates directly with the automatic storage system, our production processes can be controlled even more efficiently. This is an advantage that points towards Industry 4.0 in the metal industry.”

The company continues to work with the four stations that were already available to SEEGER before the expansion. These include a goods-in and goods-out station, as well as three stations that the warehouse uses to manually supply a TruLaser 5040 laser cutting machine.

Thanks to the automatic connection of a laser cutting machine, SEEGER Lasertechnik achieves greater productivity

Permanent availability

In view of the extensions that STOPA carried out in July 2015, it was necessary to adapt the system control to the current situation. In addition to the existing interface to the STOPA WMS, an interface to the automatic handling system was implemented. Apart from that, the WMS communicates with the operator’s ERP system.

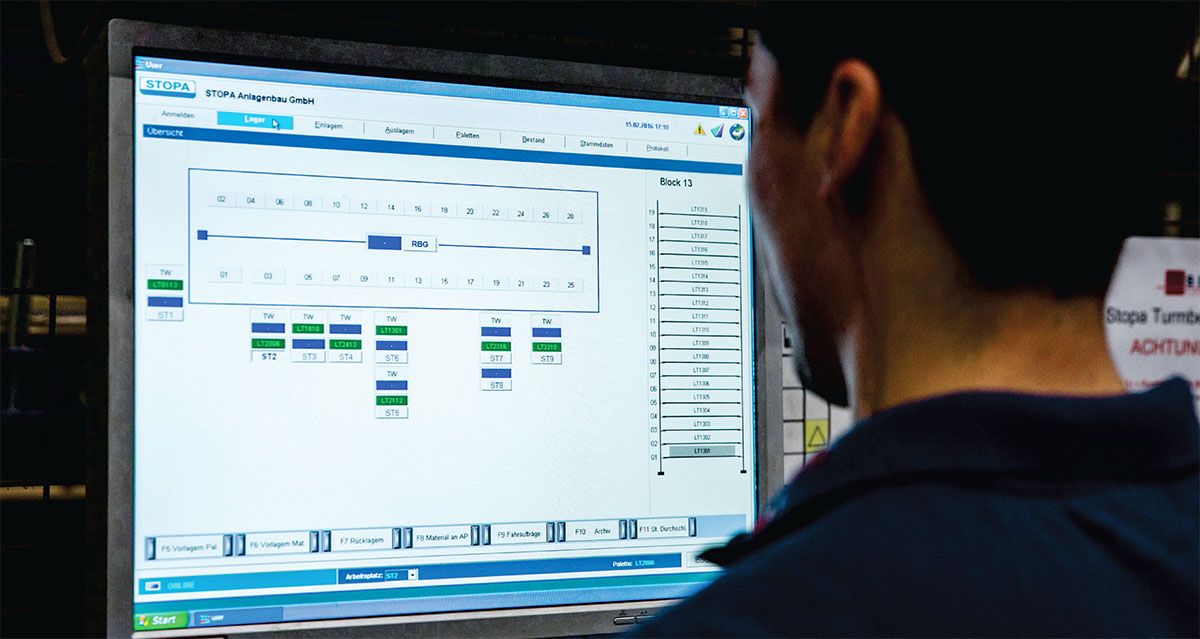

The employees find it easy to work with the system. This is based on training and the functional operating options of the sheet metal storage system via an ergonomically designed control panel with an integrated industrial PC and a 12-inch TFT display. Kiefer asks an operator to call up the status displays of the storage and retrieval machine in plain text and to have the storage blocks and the storage and retrieval machine visualized graphically. “So far, the warehouse has been running with a very high availability. This suits us because we work in three shifts, six days a week. In addition, we rely on the teleservice of the STOPA TelePresence Portal, which can be used to carry out remote diagnostics and maintenance of the system control.”

Thanks to training and the functional operating options of the sheet metal storage system, it is easy for employees to use the system

Efficiency sustainably increased

Roland Kiefer, managing partner of SEEGER Lasertechnik: “The expansion of our automated storage system is a signal, especially since it allows us to align our performance with growing demands.”

Even before the expansion, the STOPA UNIVERSAL sheet metal storage system operated by SEEGER was a significant productivity factor in sheet metal parts production. Compared to the previously selected solution, forklift traffic and thus damage to the sheets has been noticeably reduced. Furthermore, SEEGER benefits from a high level of flexibility in production, especially since the company can store sheet metal formats up to 2,000 x 4,000 millimeters ready for processing and can therefore offer a strong delivery performance. In addition, the operator has once again sustainably increased its efficiency by expanding its storage capacity and automatically connecting the laser cutting system.

Autor: Jürgen Warmbol

Sales Contact Person

Holger Dehmelt

Sales Engineer Warehouse Technology

STOPA Anlagenbau GmbH

Industriestr. 12

77855 Achern-Gamshurst

Rolf Eckhardt

Sales Engineer Warehouse Technology

STOPA Anlagenbau GmbH

Industriestr. 12

77855 Achern-Gamshurst

Andreas Pahl

Sales Engineer Warehouse Technology

STOPA Anlagenbau GmbH

Industriestr. 12

77855 Achern-Gamshurst